technical

Technical Specification for API 5L Line Pipes

Chemical Composition & Mechanical Properties for PSL 1

Chemical composition for PSL 1 pipe with t ≤ 25,0 mm (0.984 in)

| Steel grade (Steel name) |

Mass fraction, based upon heat and product analyses a % |

|||||||

| C max.b |

Mn max.b |

P |

S max. |

V max. |

Nb max. |

Ti max. |

||

| min. | max. | |||||||

| Seamless pipe | ||||||||

| L175 or A25 | 0,21 | 0,60 | - | 0,030 | 0,030 | - | - | - |

| L175P or A25P | 0,21 | 0,60 | 0,045 | 0,080 | 0,030 | - | - | - |

| L210 or A | 0,22 | 0,90 | - | 0,030 | 0,030 | - | - | - |

| L245 or B | 0,28 | 1,20 | - | 0,030 | 0,030 | c,d | c,d | d |

| L290 or X42 | 0,28 | 1,30 | - | 0,030 | 0,030 | d | d | d |

| L320 or X46 | 0,28 | 1,40 | - | 0,030 | 0,030 | d | d | d |

| L360 or X52 | 0,28 | 1,40 | - | 0,030 | 0,030 | d | d | d |

| L390 or X56 | 0,28 | 1,40 | - | 0,030 | 0,030 | d | d | d |

| L415 or X60 | 0,28e | 1,40e | - | 0,030 | 0,030 | f | f | f |

| L450 or X65 | 0,28e | 1,40e | - | 0,030 | 0,030 | f | f | f |

| L485 or X70 | 0,28e | 1,40e | - | 0,030 | 0,030 | f | f | f |

| Welded pipe | ||||||||

| L175 or A25 | 0,21 | 0,60 | - | 0,030 | 0,030 | - | - | - |

| L175P or A25P | 0,21 | 0,60 | 0,045 | 0,080 | 0,030 | - | - | - |

| L210 or A | 0,22 | 0,90 | - | 0,030 | 0,030 | - | - | - |

| L245 or B | 0,26 | 1,20 | - | 0,030 | 0,030 | c,d | c,d | d |

| L290 or X42 | 0,26 | 1,30 | - | 0,030 | 0,030 | d | d | d |

| L320 or X46 | 0,26 | 1,40 | - | 0,030 | 0,030 | d | d | d |

| L360 or X52 | 0,26 | 1,40 | - | 0,030 | 0,030 | d | d | d |

| L390 or X56 | 0,26 | 1,40 | - | 0,030 | 0,030 | d | d | d |

| L415 or X60 | 0,26e | 1,40e | - | 0,030 | 0,030 | f | f | f |

| L450 or X65 | 0,26e | 1,45e | - | 0,030 | 0,030 | f | f | f |

| L485 or X70 | 0,26e | 1,65e | - | 0,030 | 0,030 | f | f | f |

a 0,50 % maximum for copper; 0,50 % maximum fo Nickel; 0,50 % maximum for chromium; and 0,15 % maximum formolybdenum.

For grades up to and including L360/X52, Cu, Cr and Ni shall not be added intentionally.

b For each reduction of 0,01 % below the specified maximum concentration for carbon, an increase of 0,05 % above the specified maximum concentration for manganese is permissible, up to a maximum of 1,65 % for grades ≥ L245 or B, but ≤ L360 or X52; up to a maximum of 1,75 % for grades >L360 or X52, but <L485 or X70; and up to a maximum of 2,00 % for grade L485 or X70.

c Unless otherwise agreed, the sum of the niobium and vanadium contents shall be ≤ 0,06 %.

d The sum of the niobium, vanadium and titanium concentrations shall be ≤ 0,15 %.

e Unless otherwise agreed.

f Unless otherwise agreed, the sum of the niobium, vanadium and titanium concentrations shall be ≤ 0,15 %.

API 5L PSL 1 Pipe Mechanical Properties Table

| Pipe Grade | Pipe body of seamless and welded pipes | Weld seam of EW, SAW and COW pip | ||

| Yield strength R10,5 MPa(psi) minimum |

Tensile strength Rm MPa(psi) minimum |

Elongation Af % minimum |

Tensile strength Rm MPa(psi) minimum |

|

| L175 or A25 | 175 (25 400) | 310 (45 000) | c | 310 (45 000) |

| L175P or A25P | 175 (25 400) | 310 (45 000) | c | 310 (45 000) |

| L210 or A | 210 (30 500) | 335 (48 600) | c | 335 (48 600) |

| L245R or BR L245 or B |

245 (35 500) | 415 (60 200) | c | 415 (60 200) |

| L290R or X42R L290 or X42 |

290 (42 100) | 415 (60 200) | c | 415 (60 200) |

| L320 or X46 | 320 (46 400) | 435 (63 100) | c | 435 (63 100) |

| L360 or X52 | 360 (52 200) | 460 (66 700) | c | 460 (66 700) |

| L390 or X56 | 390 (56 600) | 490 (71 100) | c | 490 (71 100) |

| L415 or X60 | 415 (60 200) | 520 (75 400) | c | 520 (75 400) |

| L450 or X65 | 450 (65 300) | 535 (77 600) | c | 535 (77 600) |

| L485 or X70 | 485 (70 300) | 570 (82 700) | c | 570 (82 700) |

aFor intermediate grades, the difference between the specified minimum tensile strength and the specified minimum yield strength for the pipe body shall be as given in the table for the next higher grade.

bFor intermediate grades, the specified minimum tensile strength for the weld seam shall be the same value as was determined for the pipe body using footnote a).

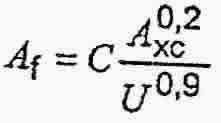

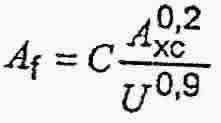

cThe specified minimum elongation, Af expressed in percent and rounded to the nearest percent, shall be as determined using the following equation;

where

C is 1 940 for calculations using SI units and 625 000 for calculations using USC units;

Axc is the applicable tensile test piece cross-sectional area, expressed in square millimetres (square inches), as follows:

----- for circular cross-section test pieces, 130 mm2 (0.20 in2) for 12,5 mm (0.500 in) and 8,9 mm (0.350 in) diameter test pieces; and 65 mm2(0.10 in2) for 6,4 mm (0.250 in) diameter test pieces;

------ for full-section test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified outside diameter and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.01 in2);

----- for strip test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified width of the test piece and the specified wall thickness of the pipe, rounded to the nearest 10 mm2(0.01 in2);

U is the specified minimum tensile strength, expressed in megapascals (pounds per square inch).

Chemical Composition & Mechanical Properties for PSL 2

Chemical composition for PSL 2 pipe with t ≤ 25,0 mm (0.984 in)

| Steel grade (steel name) | Mass fraction, based upon heat and product analyses % maximum |

Carbon equivalenta % maximum |

|||||||||

| C b | Si | Mn b | P | S | V | Nb | Ti | Other | CEiiw | CEpcm | |

| Seamless and welded pipes | |||||||||||

| L245R or BR | 0,24 | 0,40 | 1,20 | 0,025 | 0,015 | c | c | 0,04 | e | 0,43 | 0,25 |

| L290R or X42R | 0,24 | 0,40 | 1,20 | 0,025 | 0,015 | 0,06 | 0,05 | 0,04 | e | 0,43 | 0,25 |

| L245N or BN | 0,24 | 0,40 | 1,20 | 0,025 | 0,015 | c | c | 0,04 | e | 0,43 | 0,25 |

| L290N or X42N | 0,24 | 0,40 | 1,20 | 0,025 | 0,015 | 0,06 | 0,05 | 0,04 | e | 0,43 | 0,25 |

| L320N or X46N | 0,24 | 0,40 | 1,40 | 0,025 | 0,015 | 0,07 | 0,05 | 0,04 | d,e | 0,43 | 0,25 |

| L360N or X52N | 0,24 | 0,45 | 1,40 | 0,025 | 0,015 | 0,10 | 0,05 | 0,04 | d,e | 0,43 | 0,25 |

| L390N or X56N | 0,24 | 0,45 | 1,40 | 0,025 | 0,015 | 0,10f | 0,05 | 0,04 | d,e | 0,43 | 0,25 |

| L415N or X60N | 0,24f | 0,45f | 1,40f | 0,025 | 0,015 | 0,10f | 0,05 | 0,04f | g,h | as agreed | |

| L245Q or BQ | 0,18 | 0,45 | 1,40 | 0,025 | 0,015 | 0,05 | 0,05 | 0,04 | e | 0,43 | 0,25 |

| L290Q or X42Q | 0,18 | 0,45 | 1,40 | 0,025 | 0,015 | 0,05 | 0,05 | 0,04 | e | 0,43 | 0,25 |

| L320Q or X46Q | 0,18 | 0,45 | 1,40 | 0,025 | 0,015 | 0,05 | 0,05 | 0,04 | e | 0,43 | 0,25 |

| L360Q or X52Q | 0,18 | 0,45 | 1,50 | 0,025 | 0,015 | 0,05 | 0,05 | 0,04 | e | 0,43 | 0,25 |

| L390Q or X56Q | 0,18 | 0,45 | 1,50 | 0,025 | 0,015 | 0,07 | 0,05 | 0,04 | d,e | 0,43 | 0,25 |

| L415Q or X60Q | 0,18f | 0,45f | 1,70f | 0,025 | 0,015 | g | g | g | h | 0,43 | 0,25 |

| L450Q or X65Q | 0,18f | 0,45f | 1,70f | 0,025 | 0,015 | g | g | g | h | 0,43 | 0,25 |

| L485Q or X70Q | 0,18f | 0,45f | 1,80f | 0,025 | 0,015 | g | g | g | h | 0,43 | 0,25 |

| L555Q or X80Q | 0,18f | 0,45f | 1,90f | 0,025 | 0,015 | g | g | g | i,j | as agreed | |

| Welded pipe | |||||||||||

| L245M or BM | 0,22 | 0,45 | 1,20 | 0,025 | 0,015 | 0,05 | 0,05 | 0,04 | e | 0,43 | 0,25 |

| L290M or X42M | 0,22 | 0,45 | 1,30 | 0,025 | 0,015 | 0,05 | 0,05 | 0,04 | e | 0,43 | 0,25 |

| L320M or X46M | 0,22 | 0,45 | 1,30 | 0,025 | 0,015 | 0,05 | 0,05 | 0,04 | e | 0,43 | 0,25 |

| L360M or X52M | 0,22 | 0,45 | 1,40 | 0,025 | 0,015 | d | d | d | e | 0,43 | 0,25 |

| L390M or X56M | 0,22 | 0,45 | 1,40 | 0,025 | 0,015 | d | d | d | e | 0,43 | 0,25 |

| L415M or X60M | 0,12f | 0,45f | 1,60f | 0,025 | 0,015 | g | g | g | h | 0,43 | 0,25 |

| L450M or X65M | 0,12f | 0,45f | 1,60f | 0,025 | 0,015 | g | g | g | h | 0,43 | 0,25 |

| L485M or X70M | 0,12f | 0,45f | 1,70f | 0,025 | 0,015 | g | g | g | h | 0,43 | 0,25 |

| L555M or X80M | 0,12f | 0,45f | 1,85f | 0,025 | 0,015 | g | g | g | i | 0,43f | 0,25 |

| L625M or X90M | 0,10 | 0,55f | 2,10f | 0,020 | 0,010 | g | g | g | i | --- | 0,25 |

| L690M or X100M | 0,10 | 0,55f | 2,10f | 0,020 | 0,010 | g | g | g | i,j | 0,25 | |

| L830M or X120M | 0,10 | 0,55f | 2,10f | 0,020 | 0,010 | g | g | g | i,j | 0,25 | |

Table ---Chemical composition for PSL 2 pipe with t ≤ 25,0 mm (0.984 in) (Continued)

a Based upon product analysis. For seamless pipe with t > 20,0 mm (0.787 in), the carbon equivalent limits shall be as agreed. The CEiiw limits apply if the carbon mass fraction is greater than 0,12 % and the CEpcm limits apply if the carbon mass fraction is less than or equal to 0,12 %.

b For each reduction of 0,01 % below the specified maximum for carbon, an increase of 0,05 % above the specified maximum for manganese is permissible, up to a maximum of 1,65 % for grades ≥ L245 or B, but ≤ L360 or X52; up to a maximum of 1,75 % for grades >L360 or X52, but < L485 or X70; up to a maximum of 2,00 % for grades ≥L485 or X70, but ≤ L555 or X80; and up to a maximum of 2,20 % for grades >L555 or X80.

c Unless otherwise agreed , the sum of the niobium and vanadium concentrations shall be ≤ 0,06 %.

d The sum of the niobium, vanadium and titanium concentrations shall be ≤ 0,15 %.

e Unless otherwise agreed, 0,50 % maximum for copper, 0,30 % maximum for nickel, 0,30 % maximum for chromium and 0,15 % maximum for molybdenum.

f Unless otherwise agreed.

g Unless otherwise agreed, the sum of the niobium, vanadium and titanium concentrations shall be ≤ 0,15 %.

h Unless otherwise agreed, 0,50 % maximum for copper, 0,50 % maximum for Nickel, 0,50 % maximum for chromium and 0,50 % maximum for molybdenum.

i Unless otherwise agreed, 0,50 % maximum for copper, 1,00 % maximum for nickel, 0,50 % maximum for chromium and 0,50 % maximum for molybdenum.

j 0,004 % maximum for boron.

Chemical compostion

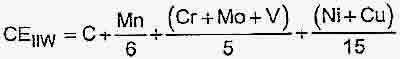

9.2.4 For PSL 2 pipe with a product analysis carbon mass fraction equal to or less than 0,12 %, the carbon equivalent, CEpcm, shall be determined using Equation (2):

![]()

where the symbols for the chemical elements represent the mass fraction in percent (see Table 5).

.If the heat analysis for boron is less than 0,000 5 % then it is not necessary for the product analysis to include boron, and the boron content may be considered to be zero for the CEpcm calculation.

9.2.5 For PSL 2 pipe with a product analysis carbon mass fraction greater than 0,12 % the carbon equivalent, CEllw shall be determined using Equation (3):

where the symbols for the chemical elements represent the mass fraction in percent (see Table 5).

NOTE: A derogation from the ISO rules for the presentation of chemical equations has been granted for Equations (2) and (3) in deference to their longstanding use in the industry.

API 5L PSL 2 Pipe Mechanical Properties Table

| Pipe grade | Pipe body of seamless and welded pipes | Weld seam of HFW, SAW and COW pipes | |||||

| Yield strength Rto,5b MPa (psi) |

Tensile strength Rm MPa (psi) |

Ratioa,b,c Rto,5/Rm |

Elongation Af % |

Tensile strength Rm MPa (psi) |

|||

| minimum | maximum | minimum | maximum | maximum | minimum | minimum | |

| L245R or BR L245N or BN L245Q or BQ L245M or BM |

245 (35 500) |

450 e (65 300) e |

415 (60 200) |

760 (110 200) |

0,93 | f | 415 (60 200) |

| L290R or X42R L290N or X42N L290Q or X42Q L290M or X42M |

290 (42 100) |

495 (71 800) |

415 (60 200) |

760 (110 200) |

0,93 | f | 415 (60 200) |

| L320N or X46N L320Q or X46Q L320M or X46M |

320 (46 400) |

525 (76 100) |

435 (63 100) |

760 (110 200) |

0,93 | f | 435 (63 100) |

| L360N or X52N L360Q or X52Q L360M or X52M |

360 (52 200) |

530 (76 900) |

460 (66 700) |

760 (110 200) |

0,93 | f | 460 (66 700) |

| L390N or X56N L390Q or X56Q L390M or X56M |

390 (56 600) |

545 (79 000) |

490 (71 100) |

760 (110 200) |

0,93 | f | 490 (71 100) |

| L415N or X60N L415Q or X60Q L415M or X60M |

415 (60 200) |

565 (81 900) |

520 (75 400) |

760 (110 200) |

0,93 | f | 520 (75 400) |

| L450Q or X65Q L450M or X65M |

450 (65 300) |

600 (87 000) |

535 (77 600) |

760 (110 200) |

0,93 | f | 535 (77 600) |

| L485Q or X70Q L485M or X70M |

485 (70 300) |

635 (92 100) |

570 (82 700) |

760 (110 200) |

0,93 | f | 570 (82 700) |

| L555Q or X80Q L555M or X80M |

555 (80 500) |

705 (102 300) |

625 (90 600) |

825 (119 700) |

0,93 | f | 625 (90 600) |

| L625M or X90M | 625 (90 600) |

775 (112 400) |

695 (100 800) |

915 (132 700) |

0,95 | f | 695 (100 800) |

| L690M or X100M | 690 (100 100) |

840 (121 800) |

760 (110 200) |

990 (143 600) |

0,97 g | f | 760 (110 200) |

| L830M or X120M | 830 (120 400) |

1 050 (152 300) |

915 (132 700) |

1 145 (166 100) |

0,99 g | f | 915 (132 700) |

a For intermediate grades, the difference between the specified maximum yield strength and the specified minimum yield strength shall be as given in the table for the next higher grade, and the difference between the specified minimum tensile strength and the specified minimum yield strength shall be as given in the table for the next higher grade, For intermediate grades lower than Grade L555 or X80, the tensile strength shall be ≤ 760 MPa (110 200 psl). For intermediate grades higher than Grade L555 or X80, the maximum permissible tensile strength shall be obtained by interpolation. For SI units, the calculated value shall be rounded to the nearest 5 MPa. For USC units, the calculated value shall be rounded to the nearest 100 psi.

b For grades >L625 or X90, Rp0,2 applies.

c This limit applies for pipe with D >323, 9 mm (12.750 in).

d For intermediate grades, the specified minimum tensile strength for the weld seam shall be the same value as was determined for the pipe body using footnote a).

e For pipe with D<219,1 mm (8.625 in), the maximum yield strength shall be ≤495 MPa (71 800 psi).

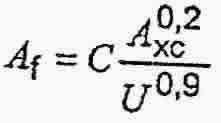

f The specified minimum elongation, Af, shall be as determined using the following equation:

Where

C is 1 940 for calculations using SI units and 625 000 for calculations using USC units;

A xc is the applicable tensile test piece cross-sectional area, expressed in square millimeters (square inches), as follows:

---- for circular cross-section test pieces, 130 mm2 (0.20 in2) for 12,5 mm (0.500 in) and 8,9 mm (0.350 in) diameter test pieces; and 65 mm2 ( 0.10 in2) for 6,4 mm (0.250 in) diameter test pieces;

---- for full-section test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified outside diameter and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.01 in2)

---- for strip test pieces, the lesser of a) 485 mm2( 0.75 in2 ) and b) the cross-sectional area of the test piece, derived using the specified width of the test piece and the specified wall thickness of the pipe, rounded to the nearest_10 mm2 (0.01 in2 );

U is the specified minimum tensile strength, expressed in megapascals (pounds per square inch).

Annex H (Normative) PSL 2 Pipe Ordered for Sour Service (Chemical & Mechanical Properties)

Chemical composition for sour service seamless pipe with t ≤ 25,0 mm (0.984 in)

| Steel grade | Mass fraction, based upon heat and product analyses % maximum |

Carbon equivalent a % maximum |

|||||||||

| C b | Si | Mn b | P | S | V | Nb | Ti | Otherc, d | CE llw | CEpcm | |

| SMLS and welded pipes | |||||||||||

| L245NS or BNS | 0,14 | 0,40 | 1,35 | 0,020 | 0,003e | f | f | 0,04 | g | 0,36 | 0,19 h |

| L290NS or X42NS | o,14 | 0,40 | 1,35 | 0,020 | 0,003e | 0,05 | 0,05 | 0,04 | - | 0,36 | 0,19 h |

| L320NS or X46NS | 0,14 | 0,40 | 1,40 | 0,020 | 0,003e | 0,07 | 0,05 | 0,04 | g | 0,38 | 0,20 h |

| L360NS or X52NS | 0,16 | 0,45 | 1,65 | 0,020 | 0,003e | 0,10 | 0,05 | 0,04 | g | 0,43 | 0,22 h |

| L245QS or BQS | 0,14 | 0,40 | 1,35 | 0,020 | 0,003e | 0,04 | 0,04 | 0,04 | - | 0,34 | 0,19 h |

| L 290QS or X42QS | 0,14 | 0,40 | 1,35 | 0,020 | 0,003e | 0,04 | 0,04 | 0,04 | - | 0,34 | 0,19 h |

| L320QS or X46QS | 0,15 | 0,45 | 1,40 | 0,020 | 0,003e | 0,05 | 0,05 | 0,04 | - | 0,36 | 0,20 h |

| L360QS or X52QS | 0,16 | 0,45 | 1,65 | 0,020 | 0,003e | 0,07 | 0,05 | 0,04 | g | 0,39 | 0,20 h |

| L390QS or X56QS | 0,16 | 0,45 | 1,65 | 0,020 | 0,003e | 0,07 | 0,05 | 0,04 | g | 0,40 | 0,21 h |

| L415QS or X60QS | 0,16 | 0,45 | 1,65 | 0,020 | 0,003e | 0,08 | 0,05 | 0,04 | g,i,k | 0,41 | 0,22 h |

| L450QS or X65QS | 0,16 | 0,45 | 1,65 | 0,020 | 0,003e | 0,09 | 0,05 | 0,06 | g,i,k | 0,42 | 0,22 h |

| L485QS or X70QS | 0,16 | 0,45 | 1,65 | 0,020 | 0,003e | 0,09 | 0,05 | 0,06 | g,i,k | 0,42 | 0,22 h |

Chemical composition for sour service welded pipe with t ≤ 25,0 mm (0.984 in)

| Steel grade | Mass fraction, based upon heat and product analyses % maximum |

Carbon equivalent a % maximum |

|||||||||

| C b | Si | Mn b | P | S | V | Nb | Ti | Otherc, d | CE llw | CEpcm | |

| SMLS and welded pipes | |||||||||||

| L245MS or BMS | 0'10 | 0,40 | 1,25 | 0,020 | 0,002e | 0,04 | 0,04 | 0,04 | - | - | 0,19 |

| L290MS or X42MS | 0'10 | 0,40 | 1,25 | 0,020 | 0,002e | 0,04 | 0,04 | 0,04 | - | - | 0,19 |

| L320MS or X46MS | 0'10 | 0,45 | 1,35 | 0,020 | 0,002e | 0,05 | 0,05 | 0,04 | - | - | 0,20 |

| L360MS or 52MS | 0'10 | 0,45 | 1,45 | 0,020 | 0,002e | 0,05 | 0,06 | 0,04 | - | - | 0,20 |

| L390MS or X56 MS | 0'10 | 0,45 | 1,45 | 0,020 | 0,002e | 0,06 | 0,08 | 0,04 | g | - | 0,21 |

| L415MS or X60MS | 0'10 | 0,45 | 1,45 | 0,020 | 0,002e | 0,08 | 0,08 | 0,06 | g,i | - | 0,21 |

| L450MS or X65MS | 0'10 | 0,45 | 1,60 | 0,020 | 0,002e | 0,10 | 0,08 | 0,06 | g,i,j | - | 0,22 |

| L485MS or X70MS | 0'10 | 0,45 | 1,60 | 0,020 | 0,002e | 0,10 | 0,08 | 0,06 | g,i,j | - | 0,22 |

a ) Based upon product analysis (see 9.2.4 and 9.2.5) The CEllw limits apply if the carbon mass fraction is greater than 0,12 % and the CEpcm limits apply if the carbon mass fraction is less than or equal to 0,12 %.

b ) For each reduction of 0,01 % below the specified maximum for carbon, an increase of 0,05 % above the specified maximum for manganese is permissible, up to a maximum increase of 0,20 %.

c ) AI total ≤ 0,060 %; N ≤ 0,012 %; AI/N ≥ 2:1 (not applicable to titanium-killed or titanium-treated steel); Cu ≤ 0,35 % (if agreed ,Cu ≤ 0,10 %); Ni ≤ 0,30 %; Cr ≤ 0,30 %; Mo ≤ 0,15 %; B ≤ 0,0005 %.

d ) For welded pipe where calcium is intentionally added, unless otherwise agreed, Ca/s ≥ 1,5 if S > 0,0015 % For SMLS and welded pipes, the calcium concentration shall be ≤ 0,006 %.

e ) The maximum limit for sulfur concentration may be increased to ≤ 0,008 % for SMLS pipe and, if agreed, to ≤ 0,006 % for welded pipe. For such higher-sulfur levels in welded pipe, lower Ca/s ratios may be agreed.

f ) Unless otherwise agreed, the sum of the niobium and vanadium concentrations shall be ≤ 0,06 %.

g ) The sum of the niobium, vanadium and titanium concentrations shall be ≤ 0,15 %.

h ) For SMLS pipe, the listed value may be increased by 0,03.

i ) If agreed, the molybdenum concentration shall be ≤ 0,35 %.

j ) If agreed, the the chromium concentration shall be ≤ 0,45 %.

k ) If agreed, Cr concentration shall be ≤ 0,45 % and Ni concentration shall be ≤ 0,50 %.

Sour Service Welded Pipe Mechanical Properties Table

| Pipe Steel Grade | Pipe body of SMLS pipes | Weld seam of HFW and SAW pipes | |||||

| Yield strength a Rto,5 Mpa (psi) |

Tensile strength a Rm Mpa (psi) |

Ratio b Rto,5/Rm |

Elongationon 50 mm or 2 in Af % |

Tensile strength c |

|||

| minimum | maximum | minimum | maximum | maximum | minimum | minimum | |

| L245NS or BNS L245QS or BQS L245MS or BMS |

245 (35 500) |

450 d (65 300) d |

415 (60 200) |

760 (110 200) |

0,93 | e | 415 (60 200) |

| L290NS or X42NS L290QS or X42QS L290MS or X42MS |

290 (42 100) |

495 (71 800) |

415 (60 200) |

760 (110 200) |

0,93 | e | 415 (60 200) |

| L320NS or X46NS L320QS or X46QS L320MS or X46MS |

320 (46 400) |

525 (76 100) |

435 (63 100) |

760 (110 200) |

0,93 | e | 435 (63 100) |

| L360NS or X52NS L360QS or X52QS L360MS or X52MS |

360 |

530 (76 900) |

460 (66 700) |

760 (110 200) |

0,93 | e | 460 (66 700) |

| L390QS or X56QS L390MS or X56MS |

390 (56 600) |

545 (79 000) |

490 (71 100) |

760 (110 200) |

0,93 | e | 490 (71 100) |

| L415QS or X60QS L415MS or X60MS |

415 (60 200) |

565 (81 900) |

520 (75 400) |

760 (110 200) |

0,93 | e | 520 (75 400) |

| L450QS or X65QS L450MS or X65MS |

450 (65 300) |

600 (87 000) |

535 (77 600) |

760 (110 200) |

0,93 | e | 535 (77 600) |

| L485MS or X70MS | 485 (70 300) |

635 (92 100) |

570 (82 700) |

760 (110 200) |

0,93 | e | 570 (82 700) |

a For intermediate grades, the difference between the specified maximum yield strength and the specified minimum yield strength shall be as given in the table for the next higher grade, and the difference between the specified minimum tensile strength and the specified minimum yield strength shall be as given in the table for the next higher grade, For intermediate grades, the tensile strength shall be ≤ 760 MPa (110 200 psi).

b This limit applies for pipe with D >323, 9 mm (12.750 in).

c For intermediate grades, the specified minimum tensile strength for the weld seam shall be the same value as was determined for the pipe body using footnote a).

d For pipe with D<219,1 mm (8.625 in), the maximum yield strength shall be ≤495 MPa (71 800 psi).

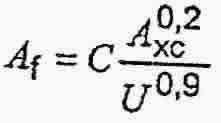

e The specified minimum elongation, Af, on 50mm or 2 in, expressed in percent and rounded to the nearest percent, shall be as determined using the following equation:

Where

C is 1 940 for calculations using SI units and 625 000 for calculations using USC units;

A xc is the applicable tensile test piece cross-sectional area, expressed in square millimeters (square inches), as follows:

---- for circular cross-section test pieces, 130 mm2 (0.20 in2) for 12,5 mm (0.500 in) and 8,9 mm (0.350 in) diameter test pieces; and 65 mm2 ( 0.10 in2) for 6,4 mm (0.250 in) diameter test pieces;

---- for full-section test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified outside diameter and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.01 in2)

---- for strip test pieces, the lesser of a) 485 mm2( 0.75 in2 ) and b) the cross-sectional area of the test piece, derived using the specified width of the test piece and the specified wall thickness of the pipe, rounded to the nearest_10 mm2 (0.01 in2 );

U is the specified minimum tensile strength, expressed in megapascals (pounds per square inch).

Annex J (normative) PSL 2 Pipes ordered for Offshore Service

Chemical composition for offsoure service seamless pipe with t ≤ 25,0 mm (0.984 in)

API 5L Steel Grade (Steel Name) |

Mass Fraction, Based Upon Heat and Product Analysis

% Maximum |

Carbon Equivalent a b % Maximum |

|||||||||

C b |

Si |

Mn b |

P

|

S |

V |

Nb |

Ti |

Otherc |

CE IIW |

CE PCM |

|

| L245NO or BNO | 0,14 |

0,40 |

1,35

|

0.020

|

0,010

|

d

|

d |

0,04 |

e,f

|

0,36

|

0,19g

|

| L290NO or X42NO | 0,14 |

0,40 |

1,35

|

0,020

|

0,010 |

0,05 |

0,05 |

0,04 |

f |

0,36 |

0,19g |

| L320NO or X46NO | 0,14 |

0,40 |

1,40

|

0,020

|

0,010 |

0,07 |

0,05 |

0,04 |

e,f |

0,38 |

0,20g |

| L360NO or X52NO | 0,16 |

0,45 |

1,65

|

0,020

|

0,010 |

0,10 |

0,05 |

0,04 |

e |

0,43 |

0,22g |

| L245QO or BQO | 0,14 |

0,40 |

1,35

|

0,020

|

0,010 |

0,04 |

0,04 |

0,04 |

f |

0,34 |

0,19g |

| L290QO or X42QO | 0,14 |

0,40 |

1,35

|

0,020

|

0,010 |

0,04 |

0,04 |

0,04 |

f |

0,34 |

0,19g |

| L320QO or X46QO | 0,15 |

0,45 |

1,40 |

0,020 |

0,010 |

0,05 |

0,05 |

0,04 |

f |

0,36 |

0,20g |

| L360QO or X52QO | 0,16 |

0,45 |

1,65 |

0,020 |

0,010 |

0,07 |

0,05 |

0,04 |

e,h |

0,39 |

0,20g |

| L390QO or X56QO | 0,16 |

0,45 |

1,65 |

0,020 |

0,010 |

0,07 |

0,05 |

0,04 |

e,h |

0,40 |

0,21g |

| L415QO or X60QO | 0,16 |

0,45 |

1,65 |

0,020 |

0,010 |

0,08 |

0,05 |

0,04 |

e,h |

0,41 |

0,22g |

| L450QO or X65QO | 0,16 |

0,45 |

1,65 |

0,020 |

0,010 |

0,09 |

0,05 |

0,06 |

e,h |

0,42 |

0,22g |

| L485QO or X70QO | 0,17 |

0,45 |

1,65 |

0,020 |

0,010 |

0,10 |

0,05 |

0,06 |

e,h |

0,42 |

0,23g |

| L555QO or X80QO | 0,17 |

0,45 |

1,85 |

0,020 |

0,010 |

0,10 |

0,06 |

0,06 |

e,h |

as agreed |

|

| L625QO or X90QO | 0,14 |

0,45 |

1,85 |

0,020 |

0,010 |

0,10 |

0,06 |

0,06 |

e,i |

as agreed |

|

| L690QO or X100QO | 0,14 |

0,45 |

1,85 |

0,020 |

0,010 |

0,10 |

0,06 |

0,06 |

e,i |

as agreed |

|

Welded Pipes

| L245MO or BMO | 0,12 |

0,40 |

1,25 |

0,020 |

0,010 |

0,04 |

0,04 |

0,04 |

f |

-- |

0,19 |

| L290MO or X42MO | 0,12 |

0,40 |

1,35 |

0,020 |

0,010 |

0,04 |

0,04 |

0,04 |

f |

-- |

0,19 |

| L320MO or X46MO | 0,12 |

0,45 |

1,35 |

0,020 |

0,010 |

0,05 |

0,05 |

0,04 |

f |

-- |

0,20 |

| L360MO or X52MO | 0,12 |

0,45 |

1,65 |

0,020 |

0,010 |

0,05 |

0,05 |

0,04 |

e,h |

-- |

0,20 |

| L390MO or X56MO | 0,12 |

0,45 |

1,65 |

0,020 |

0,010 |

0,06 |

0,08 |

0,04 |

e,h |

-- |

0,21 |

| L415MO or X60MO | 0,12 |

0,45 |

1,65 |

0,020 |

0,010 |

0,08 |

0,08 |

0,06 |

e,h |

-- |

0,21 |

| L450MO or X65MO | 0,12 |

0,45 |

1,65 |

0,020 |

0,010 |

0,10 |

0,08 |

0,06 |

e,h |

-- |

0,22 |

| L485MO or X70MO | 0,12 |

0,45 |

1,75 |

0,020 |

0,010 |

0,10 |

0,08 |

0,06 |

e,h |

-- |

0,22 |

| L555MO or X80MO | 0,12 |

0,45 |

1,85 |

0,020 |

0,010 |

0,10 |

0,08 |

0,06 |

e,h |

-- |

0,24 |

Based upon product analysis (see 9.2.4 and 9.2.5) The CE llw limits apply if the C > 0,12 % and the CE pcm limits apply if the < 0,12 %.

b For each reduction of 0,01 % below the specified maximum for C, an increase of 0,05 % above the specified maximum for Mn is permissible, up to a maximum increase of 0,20 %, but up to a maximum of 2.20% for grades ≥ L625 or X90.

c Al total ≤ 0,060 %; N ≤ 0,012 %; Al/N ≥ 2:1 (not applicable to titanium-killed or titanium-treated steel);

d Unless otherwise agreed , Nb + V ≤ 0,06 %.

e Nb + V + Ti ≤ 0,15 %.

f Cu ≤ 0,35 %; Ni ≤ 0,30 %; Cr ≤ 0,30 %; Mo ≤ 0,10 %; B ≤ 0,000 5 %.

g For SMLS pipe, the listed value is increased by 0,03 percentage points, up to a maximum of 0,25 %.

h Cu ≤ 0,50 %; Ni ≤ 0,50 %; Cr ≤ 0,50 %; Mo ≤ 0,50 %; B ≤ 0,000 5 %.

i Cu ≤ 0,50 %; Ni ≤ 0,60 %; Cr ≤ 0,55 %; Mo ≤ 0,80 %; B ≤ 0,000 5 %.

J.4.2 Tensile properties

J.4.2.1 The tensile properties shall be as given in Table J.2.

J.4.2.2 If additional tensile properties are required to be determined at other than room temperature, the acceptance criteria shall be as agreed.

Table J.2 ---Requirements for the results of tensile tests

API 5L Steel Grade |

Weld Seam of HFW, and SAW Pipes |

||||||

Yield Strength.a |

Tensile Strength.a,b |

Ratio a,c Rt0,5 / Rm |

Elongation on 50 mm or 2 in |

Tensile Strength.d |

|||

Minimum |

Maximum |

Minimum |

Maximum |

Maximum |

Minimum |

Minimum |

|

| L245NO or BNO L245QO or BQO L245MO or BMO |

245 (35 500) |

450 e (65 300) e |

415 (60 200) |

655 (95 000) |

0.93 |

f |

415 (60 200) |

| L290NO or X42NO L290QO or X42QO L290MO or X42MO |

290 (42 100) |

495 (71 800) |

415 (60 200) |

655 (95 000) |

0.93 |

f |

415 (60 200) |

| L320NO or X46NO L320QO or X46QO L320MO or X46MO |

320 (46 400) |

520 (75 000) |

435 (63 100) |

655 (95 000) |

0.93 |

f |

435 (63 100) |

| L360NO or X52NO L360QO or X52QO L360MO or X52MO |

360 (52 200) |

525 (76 000) |

460 (66 700) |

760 (110 200) |

0.93 |

f |

460 (66 700) |

| L390QO or X56QO L390MO or X56MO |

390 (56 600) |

540 (78 300) |

490 (71 100) |

760 (110 200) |

0.93 |

f |

490 (71 100) |

| L415QO or X60QO L415MO or X60MO |

415 (60 200) |

565 (81 900) |

520 (75 400) |

760 (110 200) |

0.93 |

f |

520 (75 400) |

| L450QO or X65QO L450QO or X65MO |

450 (65 300) |

570 (82 700) |

535 (77 600) |

760 (110 200) |

0.93 |

f |

535 (77 600) |

| L485QO or X70QO L485MO or X70MO |

485 (70 300) |

605 (87 700) |

570 (82 700) |

760 (110 200) |

0.93 |

f |

570 (82 700) |

| L555QO or X80QO L555MO or X80MO |

555 (80 500) |

675 (97 900) |

625 (90 600) |

825 (119 700)b |

0.93 |

f |

625 (90 600) |

| L625QO or X90QO |

625 (90 600) |

745 (97 900) |

695 (100 800) |

825 (129 800)b |

0.97 h |

f |

- |

| L690QO or X100QO | 690 g (100 100) |

810 g (117 500) |

760 (110 200) |

960 (139 200)b |

0.97 i |

f |

- |

Table J.2 --Requirements for the results of tensile tests

a For intermediate grades, the difference between the specified maximum yield strength and the specified minimum yield strength shall be as given in the table for the next higher grade, and the difference between the specified minimum tensile strength and the specified minimum yield strength shall be as given in the table for the next higher grade, For intermediate grades up to Grade L320 or X46, the tensile strength shall be ≤ 655 MPa (95 000). For intermediate grades greater than Grade L320 or X46 and less than Grade L550 or X80, the tensile strength shall be ≤ 760 MPa (110 200). For intermediate grades higher than Grade L555 or X80, the maximum permissible tensile strength shall be obtained by interpolation. For SI Units, the calculated value shall be rounded to the nearest 5 MPa. FOr USC units, the calculated value shall be rounded to nearest 100 psi.

b If agreed for pipe in grades equal to or greater than Grade L555 or X80, more stringent maximum tensile strength limits may apply.

c This limit applies for pipe with D >323, 9 mm (12.750 in).

d For intermediate grades, the specified minimum tensile strength for the weld seam shall be the same value as was determined for the pipe body using footnote a).

e For pipe requiring longitudinal testing the yield strength shall be ≤495 MPa (71 800 psi).

f The specified minimum elongation, Af, on 50mm or (2 in), expressed in percent and rounded to the nearest percent, shall be as determined using the following equation:

Where

C is 1 940 for calculations using SI units and 625 000 for calculations using USC units;

A xc is the applicable tensile test piece cross-sectional area, expressed in square millimeters (square inches), as follows:

-- for circular cross-section test pieces, 130 mm2 (0.20 in2) for 12,5 mm (0.500 in) and 8,9 mm (0.350 in) diameter test pieces; and 65 mm2 ( 0.10 in2) for 6,4 mm (0.250 in) diameter test pieces;

-- for full-section test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified outside diameter & the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.01 in2)

-- for strip test pieces, the lesser of a) 485 mm2( 0.75 in2 ) and b) the cross-sectional area of the test piece, derived using the specified width of the test piece and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.01 in2 );

U is the specified minimum tensile strength, expressed in megapascals (pounds per square inch).

g For grades > L625QO or X90QO, Rp0.2 applies.

h Lower Rt0.5 /Rm ratio values may be specified by agrement for L625 or X90.

i For Grades >L625 or X90, Rp0.2 /Rm applies. Lower Rp0.2 /Rm ratio values may be specified by agrement.